Reserch & Development

Thermal spraying

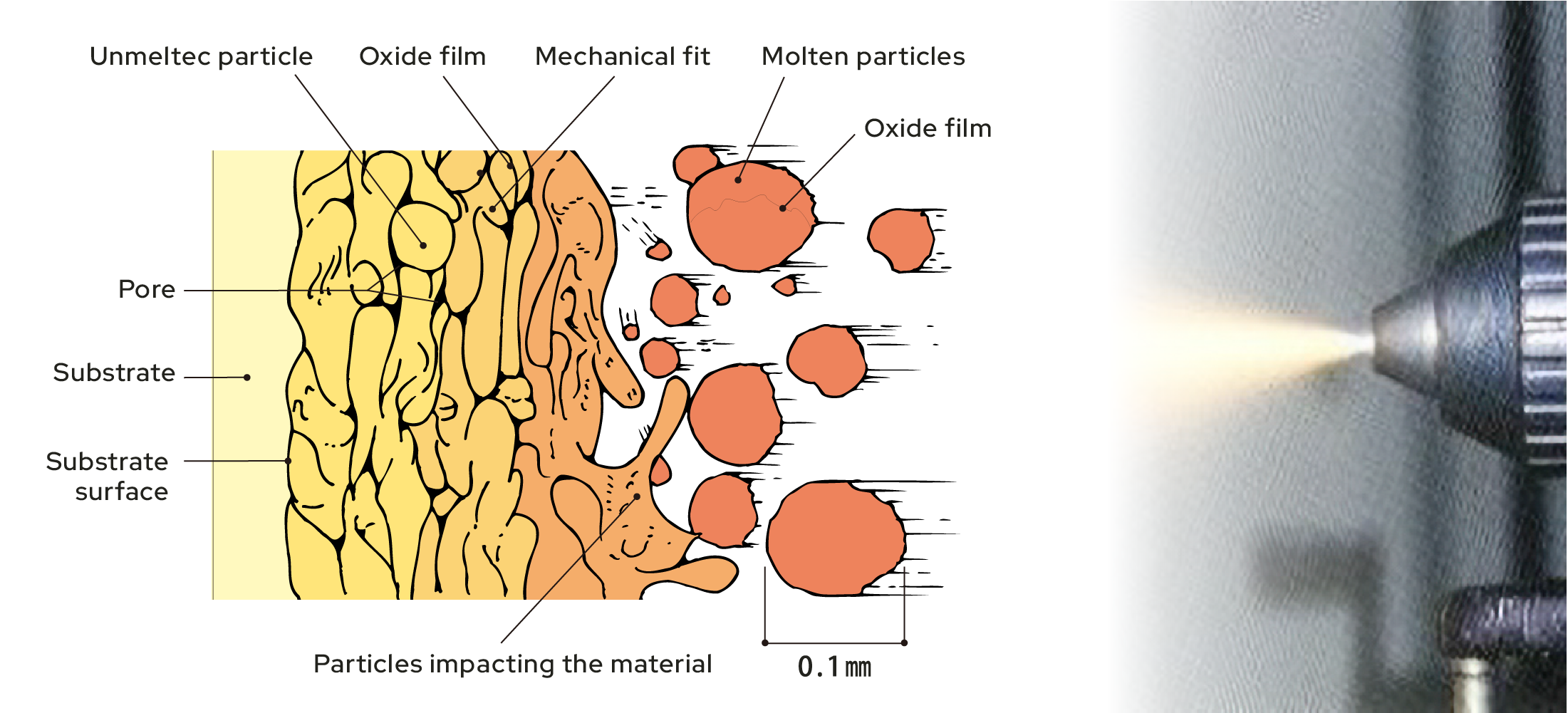

Thermal spraying is a surface modification technology in which metals and ceramics are heated to a molten or semi-molten state and then made to collide with and accumulate on the surface of a substrate thereby forming a coating.

Thermal spraying means to cause a molten material to collide with and accumulate on the surface of a substrate. Accordingly, in order to create a good thermal spray coating, a high-temperature state to create a sufficient molten state and a high-speed state to spray particles are required. In the film-creation process in thermal spraying, molten particles collide with the substrate and simultaneously become flattened. Some particles become a spray and are scattered. Particles of the raw material that have melted and become a liquid, build up rapidly to form a film.

Various Thermal spraying Methods

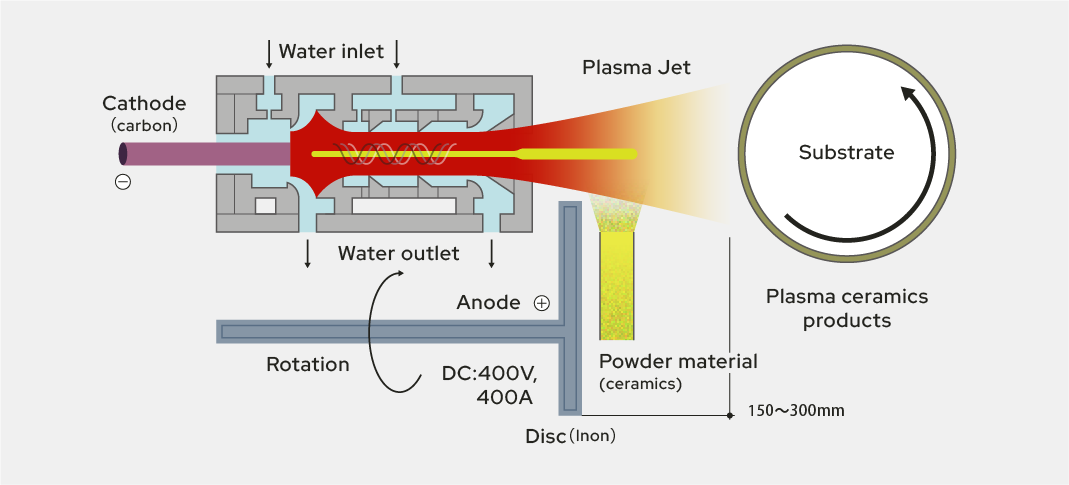

Water plasma spraying

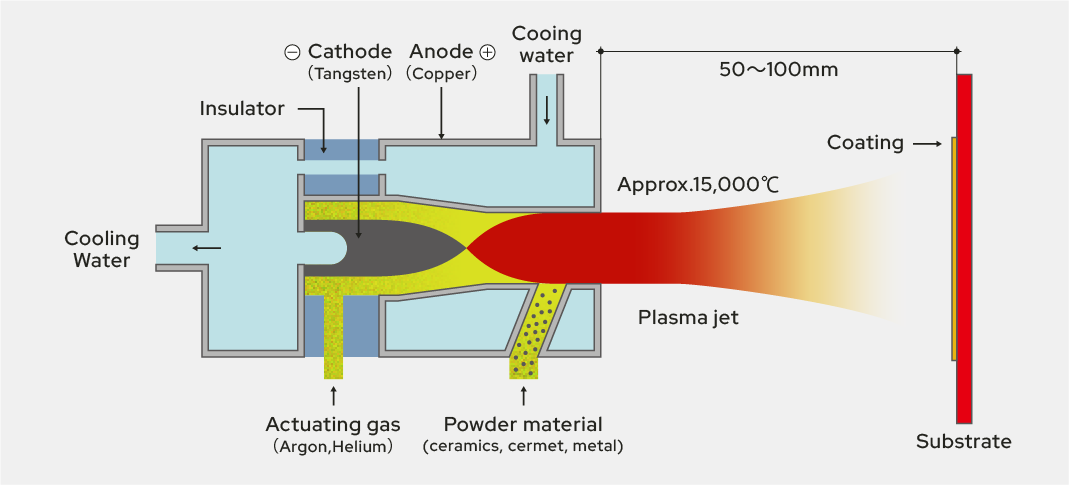

Gas plasma spraying

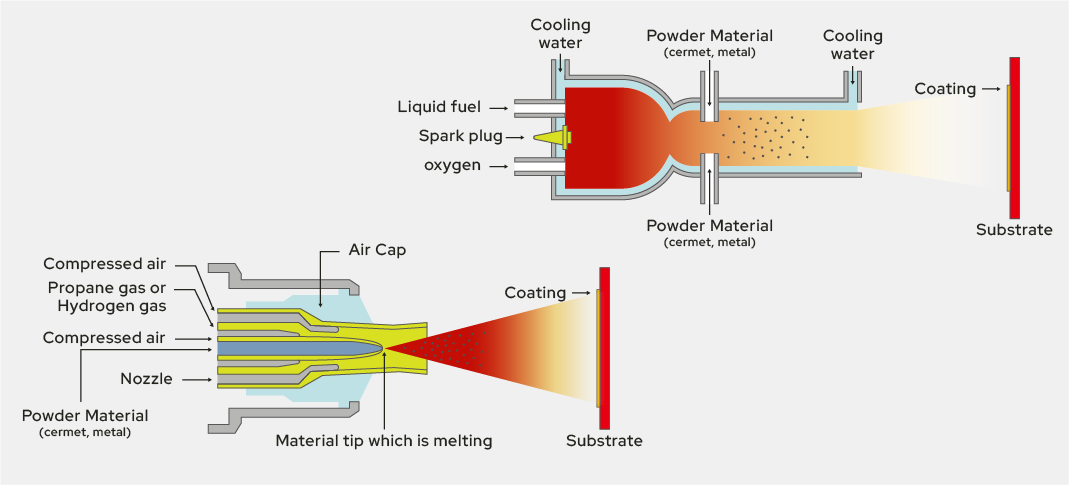

High-velocity oxygen fuel spraying

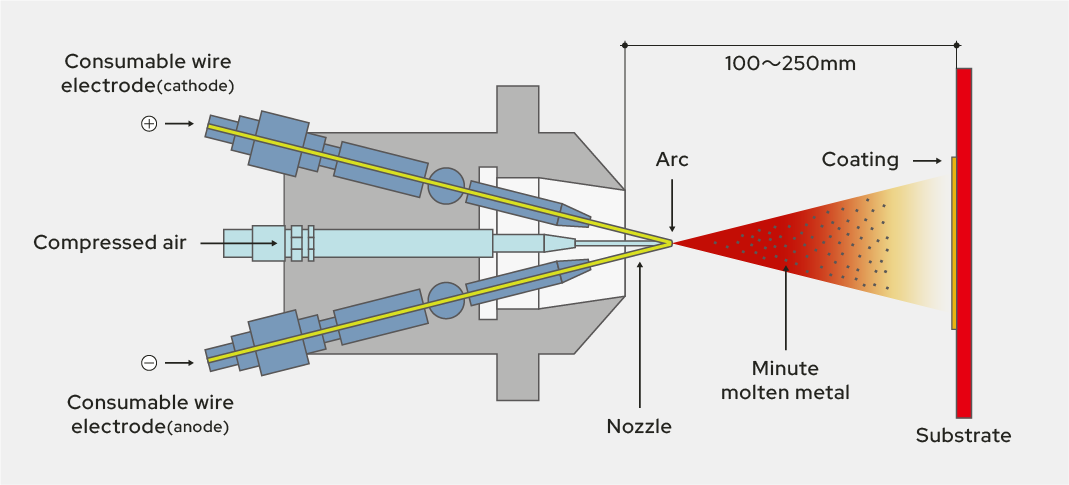

Arc spraying

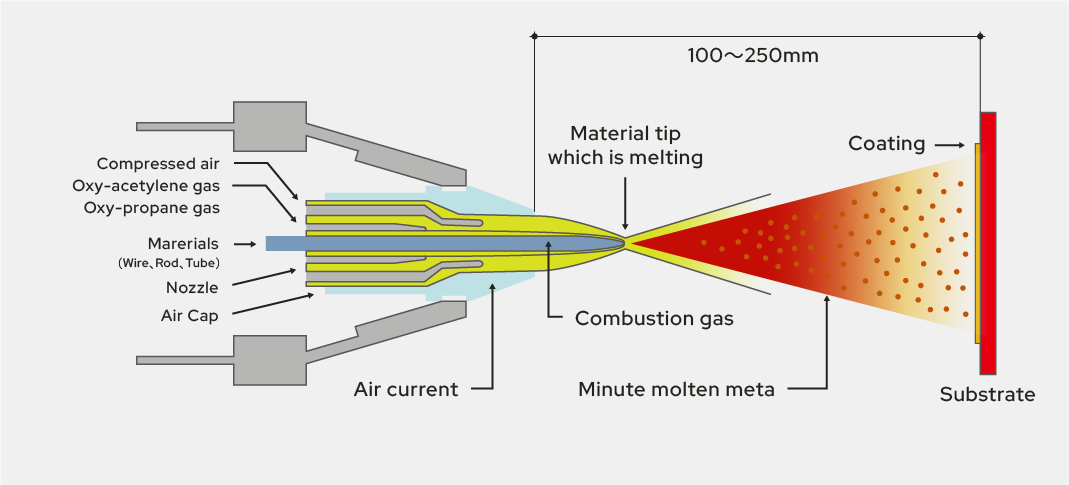

Flame spraying

Characteristics of Thermal spraying Methods

Thermal spraying, which involves the unique process of melting and projecting a solid feedstock, has characteristics that are unlike other surface modification technologies. This section provides descriptions of various surface modification technologies including thermal spraying.

Comparison of surface modification technologies

| Method | Coating materials | Substrate materials | Degree of adhesion |

|---|---|---|---|

| Thermal spraying | Metals, alloys, ceramics, plastics, glass, Cermet |

Metals, ceramics, plastics, wood, paper products |

Excellent |

| Plating | Metals, alloys | Materials that cannot be soaked in the plating solution |

Good |

| CVD (Chemical Vapor Deposition) |

Heat-resistant metals, ceramics, sulfides, selenium compounds, and others |

Materials capable of withstanding 500~2000℃and chemical corrosion by deposits |

Good |

| Vacuum deposition | Pure metals, alloys, compounds |

Any non-gas-emitting surface | Good Good when substrate heated. Excellent when substrate sputtered. |

| Ion plating | Pure metals, alloys, carbides, nitrides, oxides |

Same as above | Excellent |

Advantages and Disadvantages of thermal spraying

Advantages of thermal spraying

- Wide selection of spray materials.

- Wide selection of substrate materials.

- Speed of coating formation is fast.

- Wide range of substrate dimensions.

- On-site work possible.

- Coating can be formed while keeping substrate at low temperature.

- Spraying is a dry process so environmental impact is low.

Disadvantages of thermal spraying

- Thermal spray coating does not always indicate the characteristics of the original material.

- Thick coatings are difficult to achieve.

- Low degree of adhesion (spray efficiency) on small substrates and substrates with small curvature.

- The coating formation process is not sufficiently clear and the relationship between the causes (parameters) of the application process and coating characteristics is also unexplained.

- There is no evaluation method (testing method) for assessing how well the coating has adhered to the substrate.

- Requires measures to combat noise, light, dust, fumes, and other issues.