OSAKA FUJI Corporation also has superior technological capabilities and a proven track record in the paper manufacturing industry in the field of facility repair and refurbishment. We provide overlay welding services for equipment used in the front-end process, which handles the raw materials, and thermal spraying services for equipment used in the back-end process, which is referred to as the papermaking process.

Some of the services we offer are introduced below.

Example applications of welding technology

Rotary kiln tire

Processing of an Kiln facility in a paper factory

Incinerator’s screw

Processing of the screw that transports ash after incineration

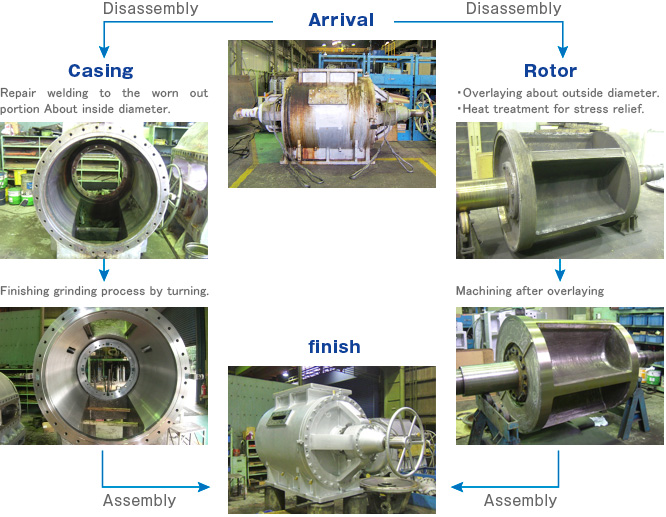

Overhaul of law pressure feeder that processed based on Valmet.K.K. manual in OFIC Amagasaki factory

Processing of equipment that supplies raw materials

Feeder overhaul procedure (Example)

Example applications of thermal spraying technology

(Processes related to thermal sprayed products)

Example applications of thermal spraying technology in the paper manfacturing field (Excerpt)

| Product | Dimensions/Form | Required Performance | Thermal Spraying Specifications |

|---|---|---|---|

| Wire roll blast roll | Φ 300(to Φ 1000) x 4000L (to 7000L) all kind | Abrasion proof, anti-corrosion |

Ceramics (water plasma thermal spraying method) + sealing treatment |

| Press roll | Φ 600(to Φ 1000) x 4000L (to 5000L) all kind | Paper separation, separation form, abrasion proof |

High hardness ceramics + sealing treatment |

| Drier roll | Φ 1500 x 5000L | Preservation | Ni composition metal spraying + sealing treatment + grinding process |

| Calendar roll | Φ 200 (to Φ 800) x 2000L (to 6000L) all kind | High hardness + abrasion proof + anti-corrosion |

WC cermet + Sealing treatment |

| Winder drum | Φ 600 x 4000L all kind | Prevension of slip, power of grip | WC cermet more than 50μm or greater Ry 30 to 50μm |

Images from the worksite

Spraying a paper machine roll using water plasma spraying

Paper machine roll after polishing

![]() Frequently asked questions related to our markets(Paper).

Frequently asked questions related to our markets(Paper).

- Do you have experience working with parts made by non-Japanese paper manufacturers?

- Can I get some detailed sales material about services you offer for the paper industry?

![]()